- …

- …

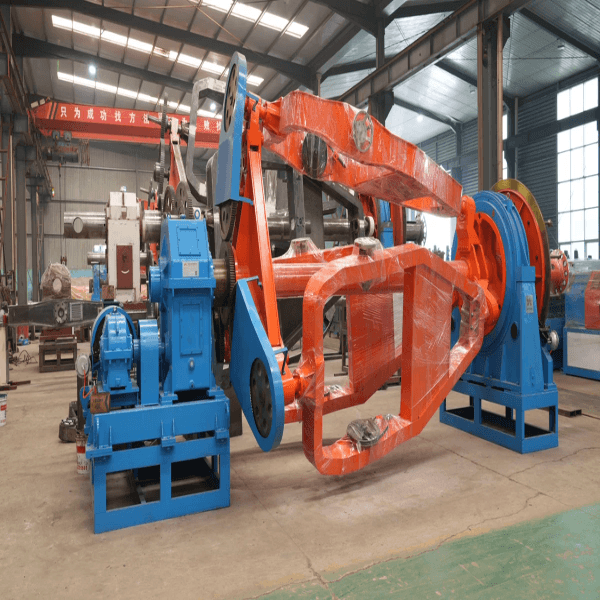

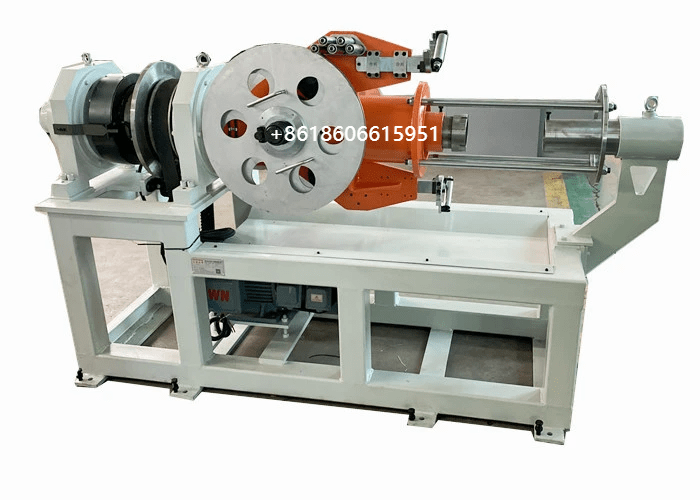

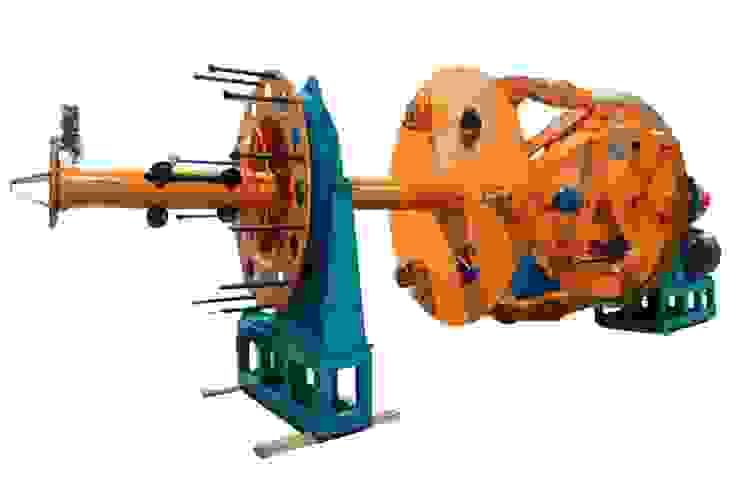

Cradle Laying-up Machine

Cradle Laying Machine, Planetary Type Laying Machine, Core Cable Stranding Machine, Planetary Cabling Machine.

Cradle Laying-up Machine Manufacturer

Application:

The machine is used for stranding copper, aluminum conductor, steel wire, rubber-insulated wires, and steel-wire armoring the cables. as well as twist galvanized steel wire rope, like OPGW, optical fiber cable, ACSR, Flexible conductors, high tensile steel wire armoring, instrument, data, control cables.

Cradle type cabling machine is an important equipment for wire and cable. It is mainly used for lay-up 3 to 6-core insulated wires, which can be used in round cables with back-twist, and stranding fan-shaped cables without back-twist. also can be used for cabling such as LV&MV power cables, control cables, mining cables, and other large-section cables. meanwhile equipped non-metal and metal tape wrapping, steel tape armoring and filling with this machine.

Our company has many years of experience in research and development of cradle type cabling machine, fully integrated the cable production process of China first-class cable manufacturers. We can provide 1000, 1250, 1600, 2000 and other models of cradle type cabling machine, and can achieve various cabling types such as 1 + 3, 1 + 1 + 3, 1 + 4, 2 + 3, etc., which effectively broaden the production range of products. It is the best equipment for mass, continuous and large-section cables.

Features

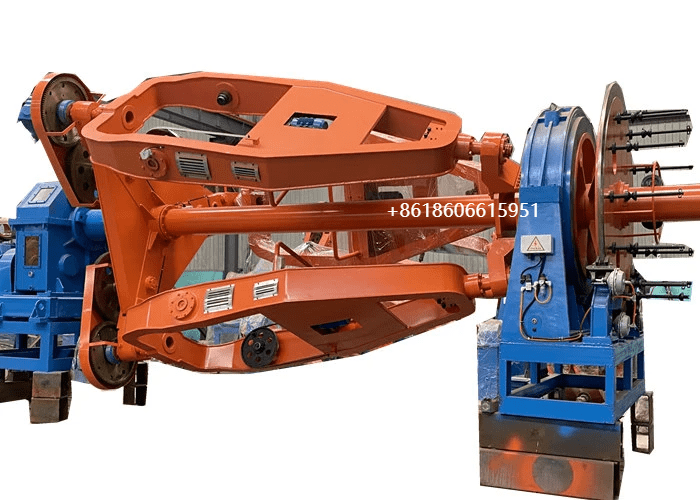

- The stranding cage is driven by a separate motor, controlled by frequency conversion, has a left-right rotation function and low running noise.

- The bobbin rack of the stranding cage adopts a cone arrangement which smoothes the wiring.

- Each bobbin rack uses a back-twist motor to run back-twisting or pre-twisting for easy control and adjustment.

- With eccentric adjustment function.

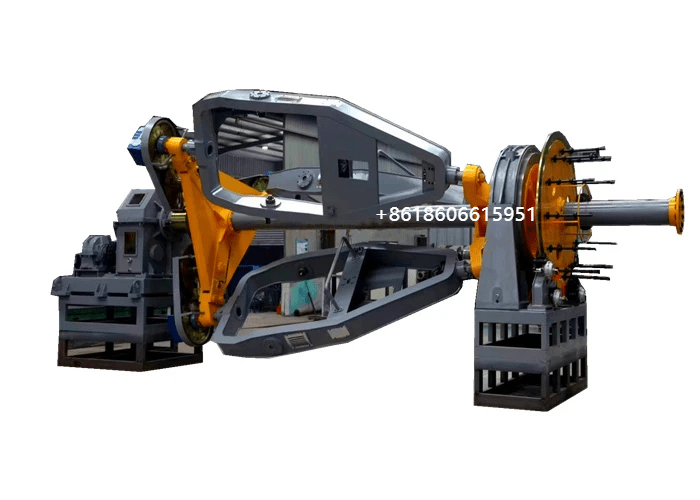

Main Components:

- Central pay-off stand.

- Stranding cage

- Assembling die holder

- Non-metal wrapping head

- Metal wrapping head

- Capstan/Hual-off/Caterpillar

- Take-up and traverse line stand

- Control system

- Transmission system

- Wearing parts.

Main Model of Core Cable Stranding Machine?

Different configurations are used according to the specifications of customer' cables.

Planetary Cabling Machine CLY800/1+6

Cabling 4-7 core wire from 5-12mm. Centralized lubricating system for gears & bearings, 100% back-twist function.

Planetary Cabling Machine CLY1000/1+4

Cabling 5 core 6-20mm insulated wire.

Adopt parallel laying-up structure. Max linear speed 34m/min.

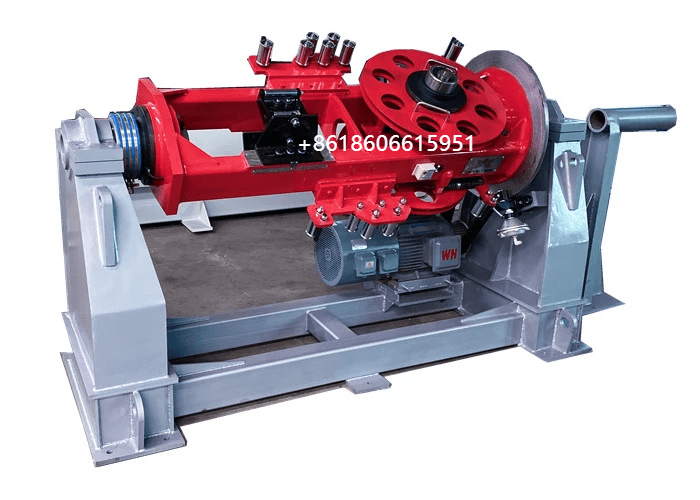

High Speed Cradle Lay-up Machine CLY1250/1+3

Max rotation speed 50r/min, use independent motor driving form with each parts such as stranding cage and capstan.

Cradle Laying-up Machine CLY1250/1+1+3

Cabling 5 core 8-25mm used for 3 cores, 4 cores and 5 cores power cable,control cables, signal cables communication cables production. And 20-185sqmm round or sector cable. Use ground shaft driving. Max rotation speed 31r/min.

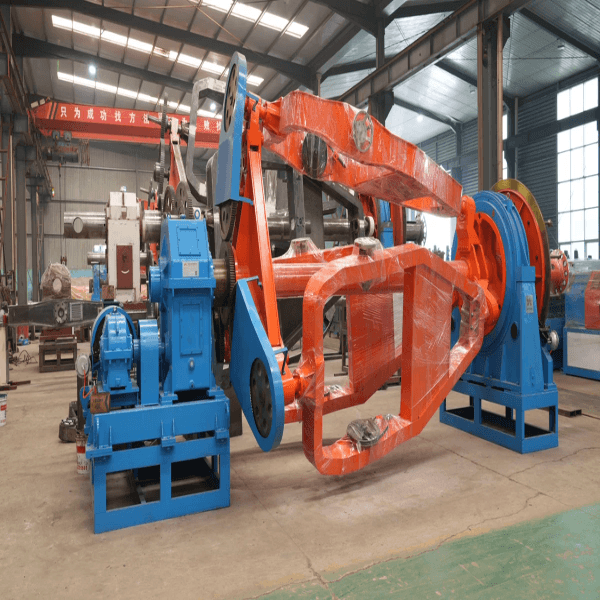

Cradle Cabling Machine CLY1600/1+3

Cabling 4 core 10-35mm is used for making PVC,PE,XLPE,RUBBER insulated power cable , tapping and armoring rubber cable, special stranded cable and so on. And 50-240sqmm round or sector cable.

Cradle Cabling Machine CLY2000/1+3

Cabling 4 core 15-40mm PVC cables, XLPE cables with or without steel armouring, mining cables, low and medium low voltage power cables. And 70-300sqmm round or sector cable.

Multi Components to Choose for your production

More components of our Planetary cabling machine for customer' cable and wire.

Portal Take-ups

Portal Take-upsPLC+touch screen control.

AC motor driving.

3-stage variable speed regulation and oil spraying lubrication.

1+1 Rotation Central Pay-off

1+1 Rotation Central Pay-offCradle frame, placed separately, adopts end shaft type,

electric clamping or loosening reel. 1250mm reel size. Pnuematic Caterpillar

Pnuematic CaterpillarThe cable is tightened and loosened pneumatically, tensioned pneumatically, driven by motor, stepless speed change

Mechanical Tension

Mechanical TensionThe pay-off tension in the cage adopts belt type mechanical friction to provide tension, manually adjustable.

Double Row Die Holder

Double Row Die HolderThe mold base adopts circular split type, Inner hole diameter of die base: 120mm.

Technical Parameter of Cradle Laying Machine

1+3/1+1+3/1+3 Cage Structure to Choose For Your Cable Production

CLY800/CLY1000

- Input wire Dia.:6-20mm

- Max stranding OD:60mm

- Max rotating speed:50r/min

- Pitch: 100-2000mm

- Pay-off bobbin:PN1000

- Max linear speed:44m/min

- Haul-off force: 1250kg

- Taping speed: 650r/min

- Main motor power:37kw

- Tale-up bobbin: PN1000-PN2000

CLY1250/1+1+3

- Input wire Dia.:6-30mm

- Max stranding OD:80mm

- Max rotating speed:50r/min

- Pitch: 100-2000mm

- Pay-off bobbin:PN1250

- Max linear speed:50m/min

- Haul-off force: 1600kg

- Taping speed: 650r/min

- Main motor power:45kw

- Tale-up bobbin: PN1250-PN2500

CLY1600/1+1+3

- Input wire Dia.:10-50mm

- Max stranding OD:120mm

- Max rotating speed:44r/min

- Pitch: 500-4000mm

- Pay-off bobbin:PN1600

- Max linear speed:44m/min

- Haul-off force: 2500kg

- Taping speed: 650r/min

- Main motor power:55kw

- Tale-up bobbin: PN1250-PN2500

CLY2000/1+1+3

- Input wire Dia.:10-60mm

- Max stranding OD:140mm

- Max rotating speed:31r/min

- Pitch: 500-4000mm

- Pay-off bobbin:PN2000

- Max linear speed:31m/min

- Haul-off force: 3200kg

- Taping speed: 650r/min

- Main motor power:75kw

- Tale-up bobbin: PN1600-PN3150

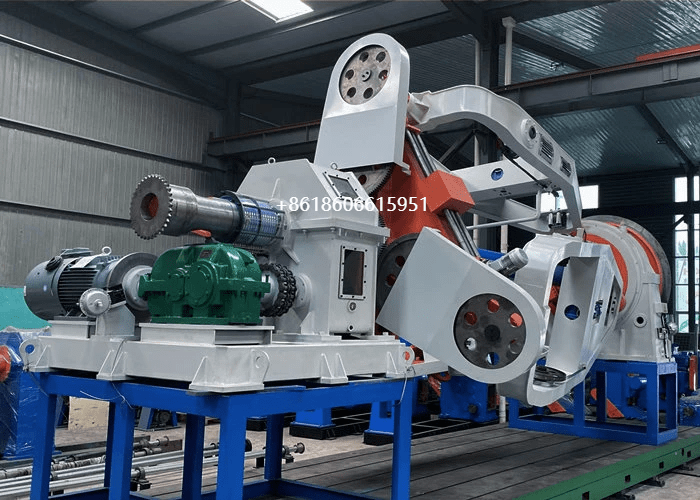

High Speed Rotating Cradle Cabling Machine

- The stranding cage is driven by a separate motor, controlled by frequency conversion, has a left-right rotation function and low running noise.

- PLC program control + touch screen + variable frequency speed control + pneumatic control.

- Each bobbin rack uses a 100% back-twist motor to run back-twisting or pre-twisting.

- Max rotation speed can reach 50r/min.

- The double support structure of front and rear large bearings is more suitable for high-speed rotation.

- The inside of the reduction box is sprayed and lubricated by the oil pump motor.

High Speed Non-metal Wrapping Machine

- Wrapping form : Tangent type

- Max diameter of applicable tape : Φ600mm

- Number of reels : 2 pad

- Max wrapping speed : 650r/min

- Tape pitch : Stepless adjustable

- Materials: polyester belt, non-woven fabric, aluminum plastic composite belt, glass cloth, semi conductive cloth, etc.

- The operation of human-machine interface touch screen is coordinated and controlled by PLC.

- The AC variable frequency motor is driven separately, and the drive motor has a built-in encoder

- Broken belt parking: it has the function of pulse vector detection and broken belt parking

- Max diameter of applicable reel: 30mm.

- Number of reels: 2 pads.

- Max rotating speed: 600rpm.

- Armoring pitch: 14.3-236.3mm (stepless adjustable).

- Mechanical friction control of tape tension.

- PLC unified and coordinated control of braking process.

- Broken tape stop: it has the function of pulse vector detection and broken tape stop.

- Full cover protect system.

Advantages of Our Cradle laying-up machine?

Overhead XLPE cable

Control Cable

Armoured Power Cable

Sector Cable

More videos of Max Xu' laying-up machine

Max Xu - Social media. and know more informations.

More Technical Sheet of Core Laying-up Machine

Линия фонарной скрутки CLY1250/1+1+3

Линия фонарной скрутки CLY1250/1+1+3 Cono Máquinas Reunidoras CLY1250/1+1+3

Cono Máquinas Reunidoras CLY1250/1+1+3 Máy bện trả xoắn CLY-1250/1+1+3

Máy bện trả xoắn CLY-1250/1+1+3Get the price of core laying machine from Max Xu

Fast quotation within 12 hours.

Questions about cradle laying-up line.

On the practical application of laying-up machine

What main feature of BEYDE laying-up machine?

What is advantage of BEYDE cable laying machine?