- …

- …

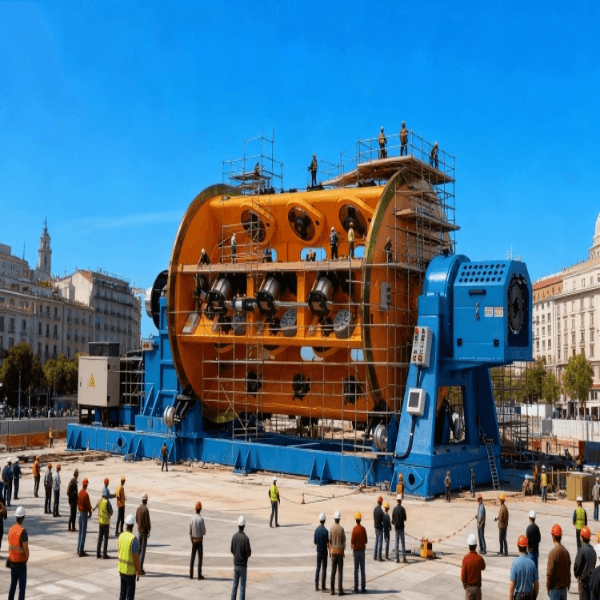

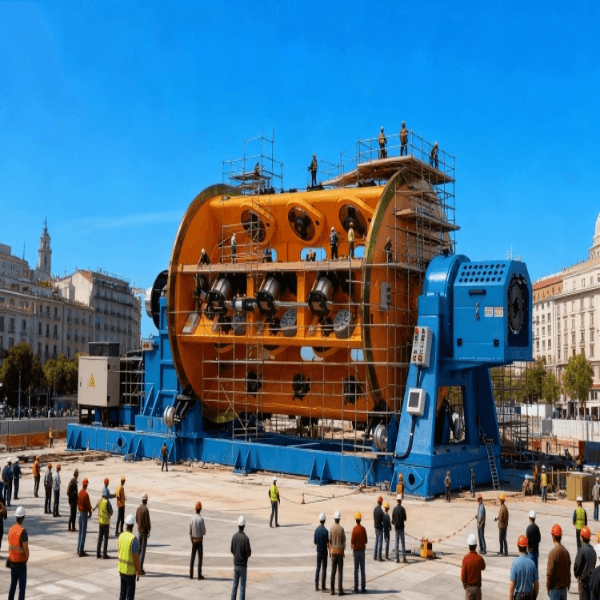

Rigid Frame Stranding Machine

Rigid Stranders, Armoring Line, Rigid Stranding Line.

High Speed Rigid Stranding Machine

Application:

The Rigid Strander/Cabler is suitable for the concentric stranding of bare conductors for low, medium and high voltage applications, Cabling insulated conductors for control cables, Screened power cables and Steel wire armouring.

- Stranding of unilay, reverse concentric, round, compressed, compacted conductors.

- Strand ACSR (Aluminum Conductor Steel Reinforced) conductors.

- Strand AAAC (All Aluminum Alloy) Conductors.

- Strand Milliken (segmented) conductors.

- Armouring and screening.

- Cabling insulated conductors for control cables.

- Typical lines include the capability to strand 19 or 91 elements in a single pass with tandemizing options to further enhance the line’s capabilities

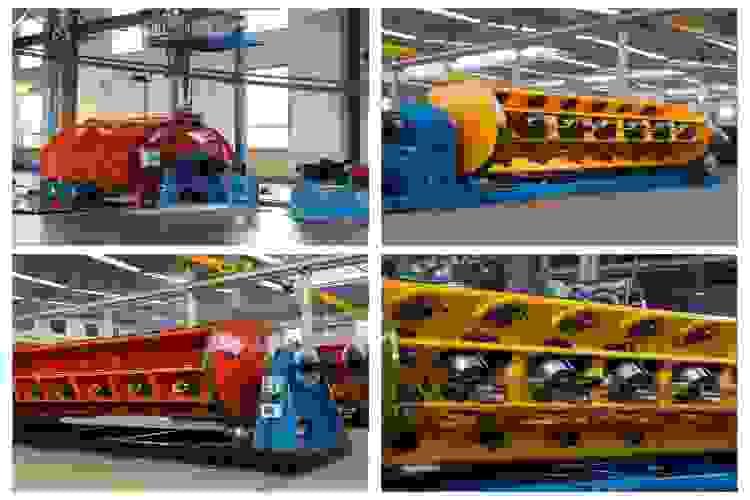

Main Components:

- Central pay-off stand.

- Pre-former

- Stranding cage

- Loading reel system

- Assembling die holder

- Rotation compact head

- Wrapping head

- Capstan/Hual-off

- Take-up and traverse line stand

- Control system

- Transmission system

- Wearing parts.

Main Model of Rigid Stranding Machine?

Machines with different configurations are used according to the specifications of customer' cables.

Rigid Stranding Machine JLK500/1+6+12+18

Mainly used for stranding 37 conductors upto 185mm2, adopt manual single bobbins loading system.

Rigid Stranding Machine JLK500/1+12+18+24

Mainly used for stranding 54 conductors upto 300mm2, and is mainly used for twisting LV, MV,HV or ACSR outer aluminum layer.

Rigid Stranding Machine JLK500/1+6+12+18+24

Mainly used for stranding 61 conductors upto 400-630mm2, adopt copper screening and armoring

Rigid Stranding Machine JLK630/12+18

Mainly used for stranding 37 conductors upto 185mm2, adopt separate motor driving.

Rigid Stranding Machine JLK630/1+6+12+18

Mainly used for stranding 54 conductors upto 300mm2, automatic loading system.

Rigid Stranding Machine JLK630/1+6+12+18+24

Mainly used for stranding 61 conductors upto 400-630mm2, separate motor driving type.

More Advanced Separate Motor Driving of Rigid Stranding Machine

- With constant and even pneumatic and mechanical tension system for brake

- Automatic stop system for wire breaking

- With continuous pneumatic supply for rotate air package, durable sealing material

- Dual capstan wheel, The pitch is infinitely adjustable

- Natural wire distribution for preventing abrasion damage of wire when stranding

- Meet to making up to 800 mm2 compacted copper conductors for XLPE insulated Cable and Milliken conductor .

- Easy maintenance, simple operation, low noise and pollution

- Independent AC variable frequency motor drives, process control stable and reliable performance

- Side or bottom side lumped loading system by automatic operation, which enhance the efficiency and more convenient.

- Full Siemens motor, inverter, IHM and NSK bearing.

Technical Parameter of Rigid Frame Strander

Different Stranding Cage Structure to Choose For Your Cable Production

JLK-500/630/6+12

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:25mm

- Max rotating speed:250r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:61m/min

- Capstan wheel Dia.: 1600mm

- Main motor power:55kw EA

- Tale-up bobbin: PN800-PN1600

JLK-500/630/6+12+18

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:35mm

- Max rotating speed:250r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:61m/min

- Capstan wheel Dia.: 2000mm

- Main motor power:75kw EA

- Tale-up bobbin: PN1000-PN2000

JLK-500/630/6+12+18+24

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:55mm

- Max rotating speed:250r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:61m/min

- Capstan wheel Dia.: 2500mm

- Main motor power:75kw EA

- Tale-up bobbin: PN1250-PN2500

JLK-500/630/12+18+24

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:55mm

- Max rotating speed:250r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:61m/min

- Capstan wheel Dia.: 2500mm

- Main motor power:75kw EA

- Tale-up bobbin: PN1250-PN2500

Max Xu offers a variety of configurations from high to low end

- Manual single loading bobbin system: use an electric wrench to load the bobbin into the winch one by one through the hanging tool. It is applicable to customers with few bobbins, limited funds and adjust wire frequently .

- Automatic side bottom 45° loading bobbin system: this type under the hydraulic side is mainly composed of reel bracket, linear track, guide support, transmission oil cylinder, hydraulic pump station, electric control system, etc. It can complete the turning, hanging, positioning, footwall, homing and other actions at one time.

- Horizontal side concentrate loading bobbin system: the horizontal angle is 90 ° to one side of the stranding cage. The loading trolley is also used to promote the horizontal movement, which can complete the one-time loading, unloading and other operations.

More Function of Rigid Stranding Machine for your production

More components of our rigid strander for customer' cable and wire.

Broken line stop

Each bobbin and drum of cage is equipped the non-contact sensor to detect the bobbin running state, as long as one of the bobbin is in wire-break.

Electric full enclosed shield

Adopt fully closed cover to make sure cage rotating under fully seal up condition, protection cover can open when bobbin-loading or cage stop.

Non-metallic wrapping head

used for winding non-woven fabrics and other materials with high speed. max 415pm, meanwhile provide high speed 650rpm type.

Rotation Compact Die Holder

For the production of split/milliken conductor. Equipped behind of stranding each stranding cage.

Pre-deformation head

There are one set of pre-spiraling and compacting head after each cage. This system is used to shape the stranded wires and conductor.

Max Xu Customer from World

This is really a part of our customers. Our customers cover more than 300 cable enterprises at home and abroad, involving energy, trade, government agencies, etc.

The longest service of the machine is 35 years, which has been fully affirmed by customers.

More videos of rigid stranding machine

Max Xu - Social media. and know more informations.

Main Details of Rigid Strander Line

Жесткорамная машина скрутки.JLK-630/1+6+12+18+24

Жесткорамная машина скрутки.JLK-630/1+6+12+18+24 Cableadoras rígidas JLK500-630/1+6+12+18+24

Cableadoras rígidas JLK500-630/1+6+12+18+24 Крутильная машина жесткорамного типа с отдельным мотором CAPSTIAN 6+12+18+24/630

Крутильная машина жесткорамного типа с отдельным мотором CAPSTIAN 6+12+18+24/630 Máquina torcedeira rígida JLK63012+18

Máquina torcedeira rígida JLK63012+18 Rigid Stranding Machine JLK-630/12+18+24 Separate Motor Driving

Rigid Stranding Machine JLK-630/12+18+24 Separate Motor Driving Rijit Büküm Makinaları JLK-630/1+6+12+18+24 RİJİT BÜKÜM HATTI

Rijit Büküm Makinaları JLK-630/1+6+12+18+24 RİJİT BÜKÜM HATTI Rotating prespiralled compacting unit

Rotating prespiralled compacting unitGet the price of rigid strander line from Max Xu

Fast quotation within 12 hours.Questions about Rigid strander line.

On the practical application of rigid frame strander.

Rigid Type Flat Steel Wire Armoring Machine?

What is low cost of rigid strander?

Configuration selection of fully automatic rigid stranding machine

Does rigid type screening machine can twist multi-copper wire?

How to make the milliken conductor?