- …

- …

6-35kVTriple-layer Co-extrusion

Dry-cure CCV LineMedium voltage triple-layer Co-extrusion Dry-cure CCV Line

35KV Triple-Layer Co-Extrusion Dry-Cure CCV Line

Application:

This production line is suitable for Cu or Al stranded wire core to make XLPE cables from 6kV to 35kV. It is of Semi-catenary type, in which the triple-layer cable is heated by means of short-circuit method, cross-linked with nitrogen gas, cooled by water is 14 sections of tubes, heat released by warm water, then cooled in cooling water trough. The XLPE cable is in accord with the standard of GB/T 1270b-2002 and GB/T 11017-2002.

Advantage description

1, The main control system is a new generation Siemens S7-1500 and TP1900 touch screen, which can be connected to the X-ray device, and reveal the corresponding measurements. The setpoint and production parameters (temperatures, pressure limits, speeds, torquelimits, cable dimensions, etc.) are stored in the HMI “recipe” database.

Most of the process & setpoint values can be logged in the Computer SQL database for analysis and a production report with statistical values can be generated per drum or batch. The computer can also be used as a remote monitoring.

Each single machine is equipped with a electrical cabinet controlled by PLC, so that the signals are not interfered and the control precision is high. The main control cabinet communicates with each single control cabinet via Profinet bus, which can realize remote control.2. CCV software: independently developed by our company with intellectual property rights; high-performance PACC intelligent operating software: with the most advanced process calculation operating system, set the parameters according to the production process, and after starting the operation, the line speed will follow the pipeline temperature automatically up to the set speed. When the machine is stopped, the line speed decreases with the pipeline temperature, and the equipment is stopped at a slow speed to reduce product waste and save costs. All production data’s can be displayed; views and curves are available for viewing .

3. SAG; for better reliability and cable stability, the SAG is equipped with 2 different control units; non-contact magnetic system and camera controller. These 2 control units can be switched.Main Parameter of 35kv Cable exturder

- Voltage level: XLPE: 6 ~ 35 kV

- Copper cross section: 35 ~ 630 mm2

- Aluminum cross section: 50 ~ 800 mm2

- Max cable weight: 10 kg / M

- Max diameter: Φ75 mm

- Extrusion thickness: Φ 65 extruder internal shielding: 0.5 ~ 4.0 mm

- Φ150 extruder Insulation layer: 2.5 ~ 16 mm

- Φ 90 extruder external shielding: 0.5 ~ 4.0 mm

- Cross-linked Tube total length: 108m

- Heating section: 36 m: 6 m x 6 Section

- Pre-cooling section: 12m: 6M x 2 Section

- Water cooling section: 54m; 6m x 9 Section

- Platform area of main building; (L*W) ≥24m x 18 m

- Third Floor height: ≥10 m

- Plant length: ≥135 m

- Nitrogen: pressure 2.0 ~ 2.5 MPa: purity 99.5%

- Consumption: 1-2 m3 / h: nitrogen storage tank capacity: 5m3

- Cooling water: pressure 0.2 ~ 06MPa; circulating water consumption 15m3/h

- Compressed air; pressure: 0.6 ~ 0.8 MPa; standard consumption: 0.8 m3 / h

- Installed capacity: 750 KVA

- Two power supply incoming lines (3 × 185 mm2 , 3 × 240 mm2).

Each Components of 35KV CCV Line

Main machine technical parameters of 35KV Extrusion Line

1600-2500mm Walk pay-off rack

Dancer

Turn Pulley A R=1000

130KN upper caterpillar 3T

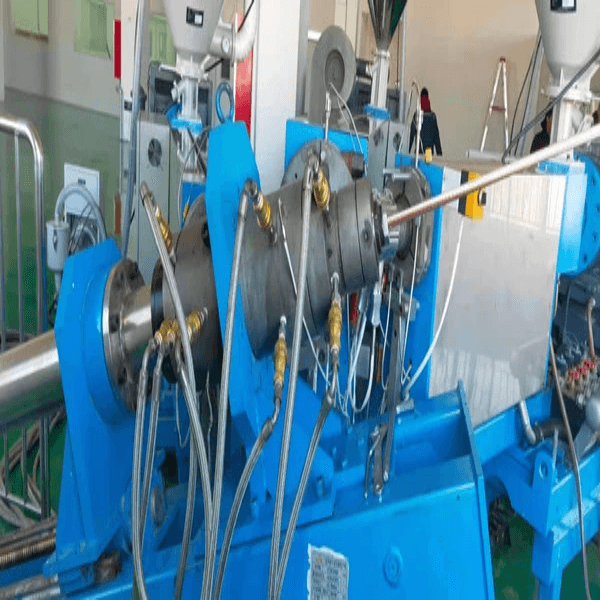

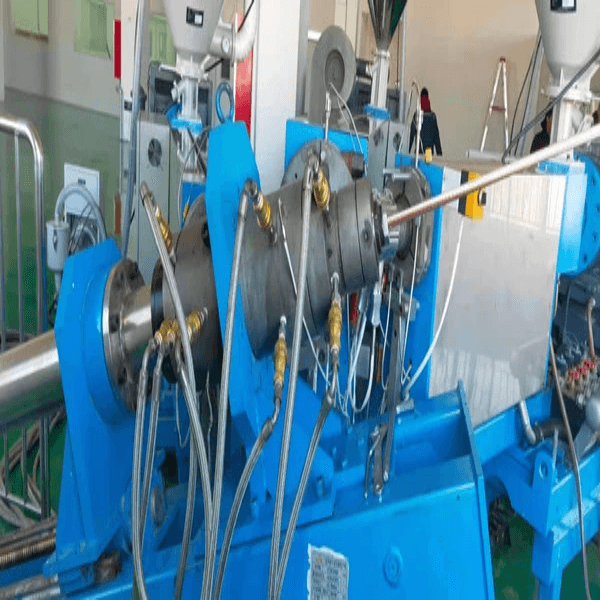

65+120+90 main extruder

Coiling and Packing Machine

CatenaryTube

30kN Lower caterpillar

3150mm Traversing Type Take-up

Electrical control system

Main equipment trademark

BEYDE provides the highest quality accessories to ensure the quality of customers' 35KV CCV Line. All accessories are internationally certified and the best choice after years of factory operation

More videos of 6-35KV CCV line

Max Xu - Social media. and know more informations.

BEYDE Customer list of 35KV Triple-Layer CCV Line

- Zhejiang Wuchan Zhongda Cable Co., Ltd,

- Hubei Lisheng Cable Co., Ltd,

- Zhejiang Zhongda Yuantong Cable Co., Ltd

- Zhejiang Wanma Cable Co., Ltd

- Zhengwei Wire and Cable Co., Ltd

- Kunming Haitian Wire and Cable Co., Ltd

- Yunnan Dongjin Cable Group Co., Ltd

- Yunnan Qianlie Cable Co., Ltd

- Yunnan Longyuan Cable Co., Ltd

- Kunming Yixian Cable Co., Ltd

- Kunming Cable Group Co., Ltd

- Kaikai Cable Technology Co., Ltd

- Yongtong Cable Co., Ltd

- Shandong Zhengwei Cable Co., Ltd

- Shandong Qufu Cable Group Company

- Hanguang Cable Shandong Linyi Factory AreaJ

- iangxi Yueguang Cable Co., Ltd

- Henan Shenghua Cable Co., Ltd

- Guangdong Nanyang Cable Co., Ltd

- Guangdong Jinlongyu Cable Co., Ltd

- Hunan Jinbei Cable Co., Ltd

Our CCV lines have been exported to Indonesia,Pakistan, and Malaysia. When customers come to the company, we can show them

the foreign trade contract.

Get the price of 35KV CCV line

Fast quotation within 12 hours.