- …

- …

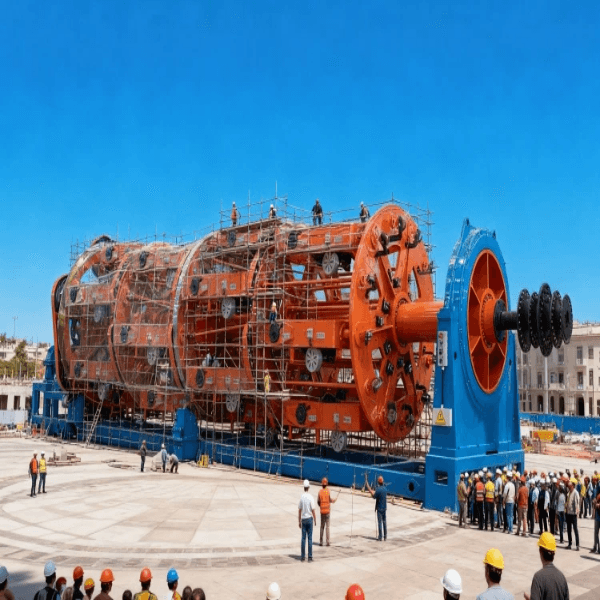

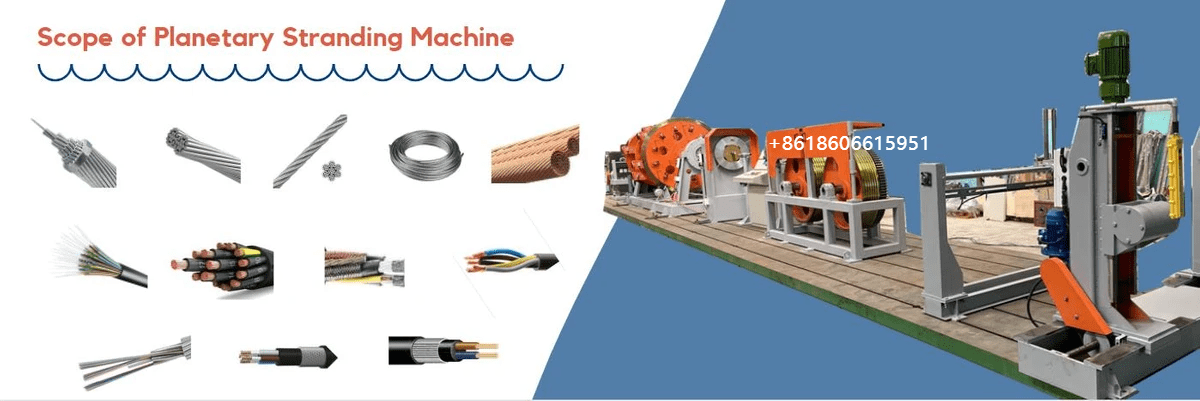

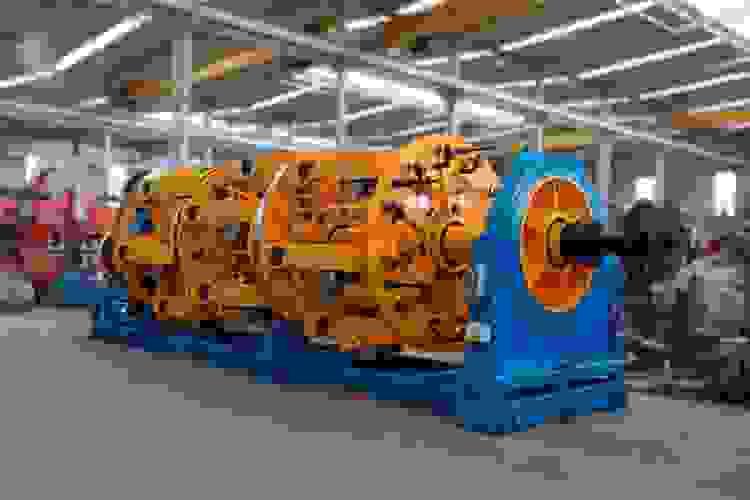

Planetary Stranding Machine

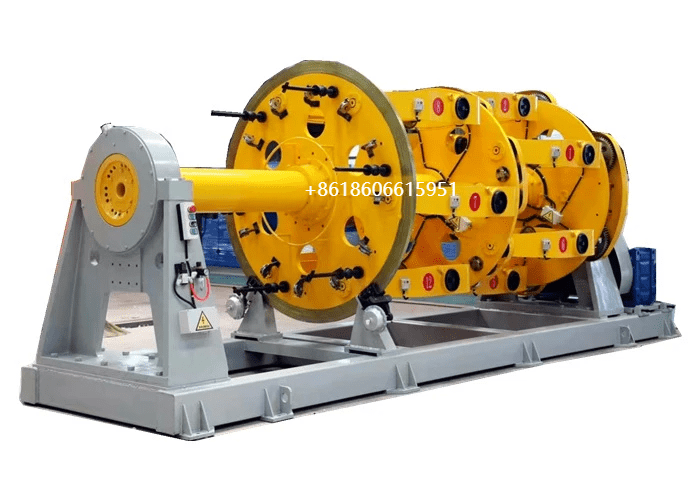

Planetary Stranders, Armoring Line, Planetary Stranding Line, Planetary Type Steel Wire Rope Closer

100% Back Twist Planetary Stranding Machine Manufacture

Application:

The machine is used for stranding copper, aluminum conductor, steel wire, rubber-insulated wires, and steel-wire armoring the cables. as well as twist galvanized steel wire rope, like OPGW, optical fiber cable, ACSR, Flexible conductors, high tensile steel wire armoring, instrument, data, control cables.

Main Features:

- The main shaft is a seamless tube, supported by double-row roller bearings on both ends.

- Each cradle is engaged by one group of gears with the back-twist gear which is around the main shaft for complete back-twisting motions.

- The wire tension is controlled by Hysteresis brake, each wire tension is kept stable and balance through PLC control.

- Back-twist and not back-twist can choose.

- Magnetic tension, mechanical tension, pneumatic tension, hysteresis tension.

- Ground shaft or separate motor driving.

Our strengths:

- PLC program control + touch screen + variable frequency speed regulation control + HMI.

- Cradle frame: it is made of steel plate by butt welding, CNC cutting plate, bending process, less welding positions, large bearing capacity, boring after overall annealing, high precision.

- Mechanical locking mechanism, the reel is not easy to throw out, and it is convenient to load and unload the reel.

- The disc air brake reduces the impact of emergency stop inertia on the transmission parts.

- Broken wire shutdown protection: both hosts are equipped with DXJ full-automatic pulse broken wire shutdown protection system.

- Double row roller self-aligning bearings are adopted for the front and rear supports of the winch cage to ensure the bearing capacity of the axial movement of the winch cage.

- The main shaft of the stranding cage is made of a whole thick wall pipe without joint.

Main Components:

- Central pay-off stand.

- Pre-former

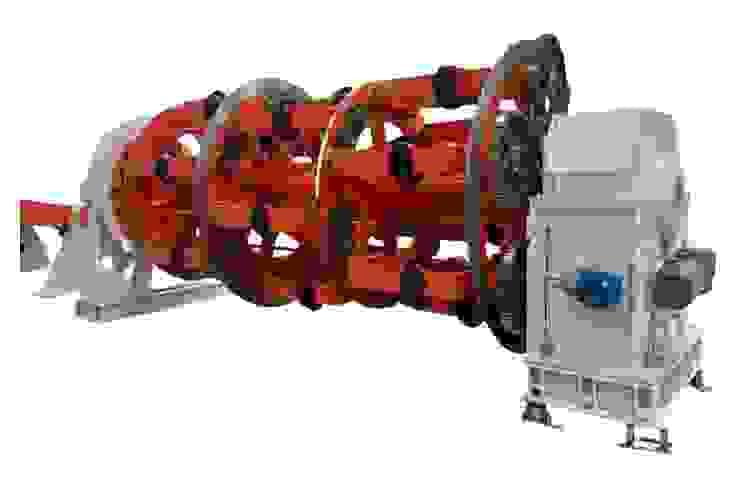

- Stranding cage

- Assembling die holder

- Non-metal wrapping head

- Metal wrapping head

- Capstan/Hual-off

- Take-up and traverse line stand

- Control system

- Transmission system

- Wearing parts.

Main Model of Planetary Strander Line?

Machines with different configurations are used according to the specifications of customer' cables.

Planetary Stranding Machine JLK315/24

Active pay-off stand.

Armouring line.

Bare wire: Ø1.0-2.0mm.

Insulated wire: Ø1.0-4mm.

Max diameter of single wire: Ø28.

Max speed of twister: 120 rpm.

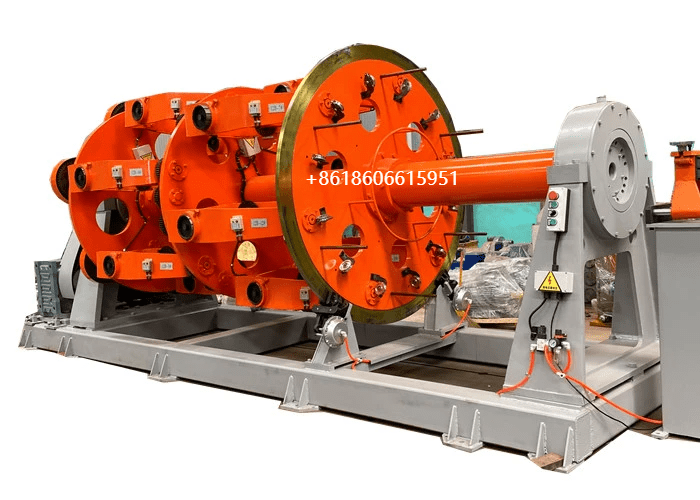

Planetary Strander Line JLK500/6+12

Hysteresis tension.

Bare wire: Ø1.0-3.5mm.

Insulated wire: Ø1.2-8.0mm.

Max diameter of single wire: Ø60.

Max speed of twister: 105 rpm.Independent motor driving

Planetary Lay-up Machine JLK500/6+12

Ground shaft driving

Bare wire: Ø1.0-3.5mm.

Insulated wire: Ø1.2-8.0mm.

Max diameter of single wire: Ø60.

Max speed of twister: 105 rpm.

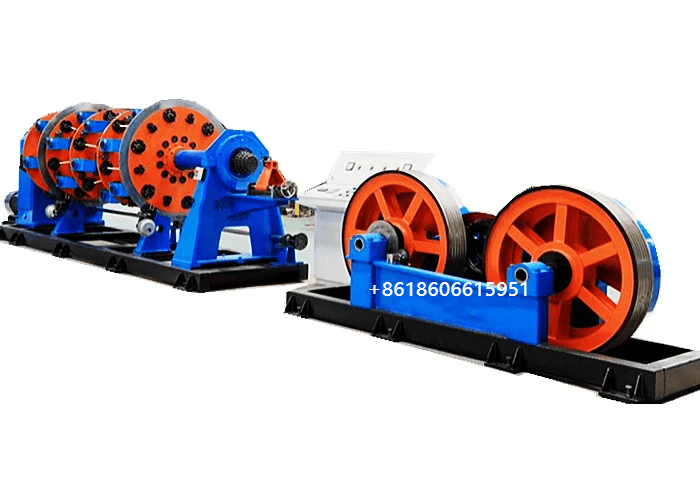

Planetary Type Cabling Machine JLK630/12+18

Ground shaft driving

Bare wire: Ø1.0-3.5mm.

Insulated wire: Ø1.5-10.0mm.

Max diameter of single wire: Ø60.

Max speed of twister: 85 rpm.

Planetary Type Armoring Machine JLK630/18

Application steel wire rope twisting

Bare wire: Ø1.0-3.5mm.

Insulated wire: Ø1.5-10.0mm.

Max diameter of single wire: Ø60.

Max speed of twister: 75 rpm.

Planetary Closer JLK800/1+8F for Steel Wire Rope

Independent motor driving

Steel wire core closer machine

Bare wire: Ø1.0-3.5mm.

Max diameter of single wire: Ø60.

Max speed of twister: 85 rpm.Multi Components to Choose for your production

More components of our Planetary strander for customer' cable and wire.

Hysteresis Tension

Then hysteresis tensioner provides the pay-off tension in cage. it can be adjusted online without shutdown through the IHM

Pre-deformation head

There are one set of pre-spiraling and compacting head after each cage. This system is used to shape the stranded wires and conductor.

Mechanical Tension

The pay-off tension in the cage adopts belt type mechanical friction to provide tension, manually adjustable.

Dual Driving Dual Wheel Capstan

Dual Driving Dual Wheel CapstanFor the production of split/milliken conductor. Equipped behind of stranding each stranding cage.

Front Side Straightening Device

Cavity size of die base : 90x90mm,Movement distance of die base: 300mm

Technical Parameter of Tubular Strander

Different Stranding Cage Structure to Choose For Your Cable Production

GJ400/1+6

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:15mm

- Max rotating speed:650r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:120m/min

- Capstan wheel Dia.: 1000mm

- Main motor power:22kw EA

- Tale-up bobbin: PN800-PN1600

GJ500/1+6

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:15mm

- Max rotating speed:650r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:120m/min

- Capstan wheel Dia.: 1000mm

- Main motor power:30kw EA

- Tale-up bobbin: PN800-PN1600

GJ630/1+6

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:15mm

- Max rotating speed:550r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:120m/min

- Capstan wheel Dia.: 1200mm

- Main motor power:45kw EA

- Tale-up bobbin: PN800-PN1600

GJ500-630/1+12

- Input wire Dia.:1.5-5.0mm Cu

- Input wire Dia.:1.8-5.0mm Al

- Max stranding OD:25mm

- Max rotating speed:350r/min

- Pitch: stepless adjust

- Pay-off bobbin:PND500/630

- Max linear speed:101m/min

- Capstan wheel Dia.: 1400mm

- Main motor power:75kw EA

- Tale-up bobbin: PN1250-PN2500

Latest Model of Planetary Strander

- Separate motor driving and hysteresis tension.

- Bearing brand:(NSK)

- Low voltage appliance brand:(SCHNEIDER)

- Brand of pneumatic component:(AIRTAC)

- Brand of main drive motor:(SIEMENS)

- Take-up motor brand:(SIEMENS)

- Frequency conversion controller:(SIEMENS )

- PLC:(SIEMENS)

- Touch screen:(SIEMENS)

- Hysteresis tension brand:(German ZF)

Anti torsion Stranding Cum Laying Machine

- ACS (aluminium Clad Steel Wire), Dia 2.0 mm – 3.65 mm.

- GSW (Galvanuzed Steel Wire), Dia 2.0 – 3.69 mm.

- SSLT (Stainless Steel Tube) for OPGW, Dia 2.0-5.0 mm.

- Al Tube (Center) for OPGW, Dia 5.2 mm - 9.7 mm.

Copper Tape Shielding Machine for Plantary Cabling Machine

- Applicable reel diameter : Ø 500mm

- Applicable tape disc aperture : Ø 160mm

- Applicable copper strip width : 20-60mm

- Maximum speed of shield head : 606r/min

- Motor power of shielding machine : 7.5KW(AC)

- Copper strip pitch range : 0 -220mm (stepless adjustment)

- Tape tension form : Hysteresis tension

- Copper tape machine is suitable for tape wrapping materials: copper, aluminum, aluminum composite tape

We are the real manufacturer of plantary strander?

Overall cutting

All main frames are cut as a whole, which is more capricious.

New design update

The appearance and function are gradually improved and continuously updated.

Precision assembly

From assembly to operation, there are experienced workers.

Supper warranty time

12 month quality assurance and lifelong technical guidance.

What kind of cable is planetary strander use for?

Our machines have been used in various cable and other fields.

More videos of Max Xu planetary stranding machine

Max Xu - Social media. and know more informations.

More Details of Planetary Strander Line

400/6+12+18 Planetary type basket strander with Reverse Twist 100% hysteresis tension

400/6+12+18 Planetary type basket strander with Reverse Twist 100% hysteresis tension Planetário mais próximo JL-315/1+30

Planetário mais próximo JL-315/1+30 Planetary Stranding Machine JLY-400/1+6+12+18+24

Planetary Stranding Machine JLY-400/1+6+12+18+24 Машина планетарной скрутки GLK-500-630/1+6+12+18+24

Машина планетарной скрутки GLK-500-630/1+6+12+18+24 CABLEADORA PLANETARIA GLK500-630/1+6+12+18+24

CABLEADORA PLANETARIA GLK500-630/1+6+12+18+24 Cordeiras Planetárias 630/1+6+12+18

Cordeiras Planetárias 630/1+6+12+18Get the price of Planetary strander line from Max Xu

Fast quotation within 12 hours.

Questions about planetary strander line.

On the practical application of planetary stranders.

What advantage of BEYDE planetary stranding machine?

What is low cost of planetary strander?

What different between hysteresis and mechanical friction tensionof planetary strander?