When customers inquire about a building wire cable extrusion line, they typically need a high-speed, precision system for producing PVC-insulated or XLPE-insulated wires (e.g., THHN, THW, building wires per IEC 60227, UL 83, BS 6004). Below is a detailed breakdown of the extrusion line components, key specifications, and common customer concerns.

Building Wire Cable Extrusion Line: A Complete Guide for Manufacturers

In the construction and electrical industries, building wires are essential for power distribution, lighting, and safety systems. To produce high-quality building wires efficiently, manufacturers rely on cable extrusion lines—sophisticated systems that apply insulation (such as PVC or XLPE) onto copper or aluminum conductors.

This blog covers:

✅ Key components of a building wire extrusion line

✅ Production specifications & material options

✅ Common challenges & solutions

✅ How to choose the right extrusion line

1. What is a Building Wire Cable Extrusion Line?

A building wire extrusion line is an automated production system that:

- Extrudes insulation (PVC, XLPE, or LSZH) onto conductors.

- Ensures precise thickness & uniformity for safety compliance.

- Operates at high speeds (up to 600 m/min) for mass production.

Common building wire types produced:

- THHN/THWN (UL standard)

- PVC-insulated wires (IEC 60227)

- XLPE-insulated cables (BS 6004, VDE)

2. Key Components of the Extrusion Line

A. Pay-Off & Tension Control

- Unwinds bare conductors (copper/aluminum) smoothly.

- Critical feature: Automatic tension control to prevent wire breaks.

B. Extruder (Single or Twin-Screw)

- Melts & applies insulation (PVC, XLPE, or LSZH).

- Temperature control: 120–220°C (varies by material).

- Screw design: L/D ratio of 25:1 for optimal melting.

C. Cross-Head & Tooling (Die & Tip)

- Shapes insulation around the conductor.

- Tungsten carbide dies ensure precision (±0.02mm).

D. Cooling System

- Water baths or air cooling solidify insulation.

- Prevents bubbles & warping.

E. Capstan & Puller

- Maintains consistent speed (up to 600 m/min).

- Servo-controlled for smooth operation.

F. Marking & Testing

- Laser/inkjet printer for cable markings (size, voltage, manufacturer).

- Spark tester detects insulation defects (0–10kV).

G. Take-Up & Coiling

- Winds finished wire onto reels/drums.

- Automatic traverse for neat winding.

3. Production Specification

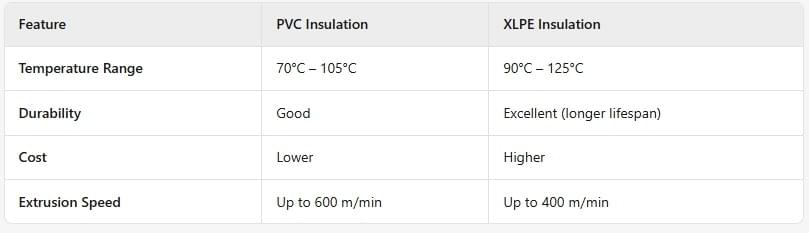

4. PVC vs. XLPE Extrusion: Which is Better?

Best for:

- PVC: General-purpose wiring (low cost, flexible).

- XLPE: High-temperature & long-lasting applications.

5. Common Challenges & Solutions

Problem 1: Insulation Thickness Variation

✅ Solution: Use automatic gauge control (AGC) with laser sensors.

Problem 2: Bubbles in Insulation

✅ Solution: Pre-dry PVC/XLPE pellets & optimize cooling.

Problem 3: Low Production Speed

✅ Solution: Upgrade to high-speed servo-driven capstans.

Problem 4: Poor Marking Legibility

✅ Solution: Install high-resolution laser printers.

6. How to Choose the Right Extrusion Line?

When selecting a building wire extrusion line, consider:

✔ Production Speed (200 m/min vs. 600 m/min)

✔ Material Compatibility (PVC, XLPE, LSZH)

✔ Automation Level (manual vs. PLC-controlled)

✔ Compliance Needs (UL, IEC, VDE)

✔ After-Sales Support (warranty, spare parts availability)

Budget Range:

- Basic line: 30,000–200,000

- High-speed automated line: 100,000–300,000+

7. Conclusion: Why Invest in a Quality Extrusion Line?

A well-designed building wire extrusion line ensures:

🔹 High productivity (up to 600 m/min)

🔹 Consistent quality (precise insulation thickness)

🔹 Lower operational costs (energy-efficient motors)

🔹 Compliance with safety standards (UL, IEC, VDE)

Next Steps:

- Request a demo from manufacturers.

- Compare technical specs (screw design, cooling efficiency).

- Ask about customization (dual-layer extrusion, marking options).

Need help choosing the right extrusion line? Contact us for Max Xu-China wire machinery expert: cabletwister@126.com